National Test House Inks MoU with DRDO’s DMSRDE to Strengthen Defence Quality Assurance

National Test House signs MoU with DRDO’s DMSRDE to boost defence materials testing, research collaboration, and quality assurance infrastructure.

Introduction: A Strategic Partnership for India’s Defence Ecosystem

In a significant move aimed at strengthening India’s defence research, testing, and quality assurance ecosystem, the National Test House (NTH) has signed a Memorandum of Understanding (MoU) with the Defence Materials and Stores Research & Development Establishment (DMSRDE), a key laboratory under the Defence Research and Development Organisation (DRDO). The collaboration marks a strategic alignment between two of India’s most established institutions, combining decades of technical expertise to support national security, industrial reliability, and self-reliance in defence manufacturing.

At a time when India is prioritizing indigenisation, quality assurance, and advanced materials research for defence applications, the agreement reflects a broader policy push toward institutional synergy and capacity building across critical sectors.

Context & Background: Two Institutions with Deep Roots

DMSRDE: A Legacy of Defence Materials Research

The Defence Materials and Stores Research & Development Establishment (DMSRDE), based in Kanpur, traces its origins back to 1929 when it was established as the Inspectorate of General Store within the Harness & Saddlery Factory in Cawnpore. Over the decades, the institution evolved in response to the growing complexity of defence requirements.

In its present form, DMSRDE was constituted in 1976 as part of DRDO through the merger of three specialized establishments—Defence Research Laboratory (Materials), Textiles and Stores Research & Development Establishment, and the Defence Institute of Stores Preservation and Packaging. Today, DMSRDE plays a pivotal role in the research and development of non-metallic materials critical to defence preparedness.

Its research portfolio spans polymers, composites, elastomers, ceramics, technical textiles, fuels, lubricants, and other specialty materials that are essential for modern defence platforms, logistics, and protective systems.

National Test House: India’s Premier Quality Assurance Backbone

The National Test House, established in 1912, is one of India’s oldest and most trusted quality testing institutions. Originally known as the Government Test House, it was founded in Calcutta by the Railway Board to support import substitution and ensure material quality for Indian Railways.

Over time, NTH expanded its mandate far beyond railways. Today, it operates under the Ministry of Consumer Affairs, Food & Public Distribution and stands as India’s largest multi-location, multidisciplinary industrial testing laboratory under the central government.

With branches in Kolkata, Mumbai, Chennai, Ghaziabad, Jaipur, Guwahati, and Varanasi, NTH provides testing, calibration, and quality evaluation services across industry, commerce, and trade, adhering to national and international standards. Its technologists actively contribute to around 150 Bureau of Indian Standards (BIS) committees and assist the National Accreditation Board for Testing and Calibration Laboratories (NABL) in strengthening India’s laboratory accreditation framework.

Main Developments: What the MoU Covers and Why It Matters

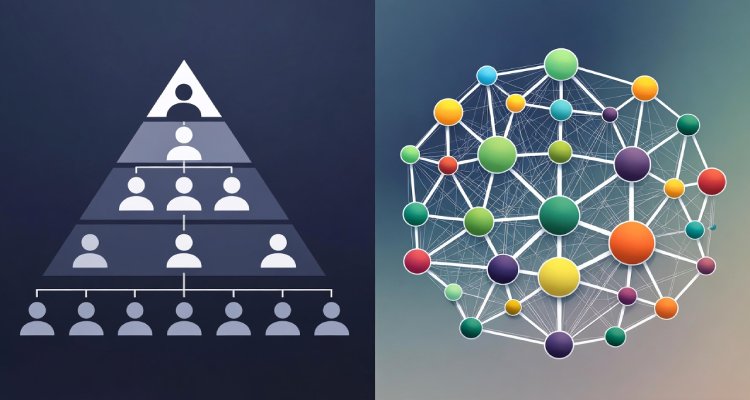

The MoU between NTH and DMSRDE establishes a formal framework for long-term cooperation in areas of mutual and national importance. At its core, the agreement aims to bridge gaps between advanced defence materials research and large-scale, standards-driven testing and evaluation.

Key Areas of Collaboration

Under the agreement, the two institutions will work together in the following areas:

- Collaborative research and testing activities to enhance the reliability and performance of defence materials

- Sharing of laboratory and advanced instrumentation facilities, especially where specialized infrastructure is not available in-house

- Exchange of scientific and technical expertise, enabling cross-pollination of knowledge

- Capacity building initiatives, including seminars, workshops, and structured training programmes

- Cooperation in nationally significant research and testing domains

The MoU also allows for mutual support in testing and evaluation services, subject to agreed terms and conditions, ensuring flexibility while maintaining rigorous standards.

Why This Collaboration Is Important

Defence materials often require complex testing under extreme conditions—thermal stress, chemical exposure, fatigue, and long-term durability. By combining DMSRDE’s materials innovation capabilities with NTH’s nationwide testing and calibration infrastructure, the partnership strengthens India’s ability to validate, certify, and deploy indigenous defence technologies efficiently.

Expert Insight: Strengthening Standards Through Collaboration

Experts in defence manufacturing and quality assurance view the MoU as a timely and pragmatic step. Collaborative frameworks like this reduce duplication of effort, accelerate testing timelines, and ensure that cutting-edge research transitions smoothly into deployable solutions.

Industry observers note that the partnership also reinforces India’s standards ecosystem. With NTH technologists deeply involved in BIS committees and DMSRDE contributing domain-specific defence expertise, the collaboration is expected to improve the alignment between research outcomes, testing protocols, and national standards.

There is also optimism that such institutional cooperation will enhance skill development among scientific and technical personnel, creating a more agile and future-ready workforce.

Impact & Implications: What Happens Next

Boost to Indigenous Defence Manufacturing

The MoU aligns closely with India’s broader push for self-reliance in defence production. Reliable testing and evaluation are critical to ensuring that indigenously developed materials meet operational requirements. The partnership strengthens this backbone, supporting both public sector defence units and private manufacturers.

Enhanced National Testing Infrastructure

By enabling shared access to laboratories and instrumentation, the collaboration optimizes the use of existing infrastructure while expanding testing capabilities. This is particularly important in high-end materials research, where specialized facilities are expensive and technically demanding.

Long-Term Capacity Building

Training programmes, workshops, and expert exchanges under the MoU are expected to build long-term institutional capacity. Over time, this could contribute to faster innovation cycles, improved compliance with global standards, and greater credibility for Indian defence materials in international markets.

Conclusion: A Quiet but Powerful Step Forward

The MoU between National Test House and DRDO’s DMSRDE may not grab headlines like weapons trials or defence deals, but its significance is profound. By strengthening the foundations of research, testing, and quality assurance, the agreement addresses one of the most critical yet often overlooked aspects of defence preparedness.

As India continues to modernize its armed forces and reduce dependence on imports, partnerships like this will play a decisive role in ensuring that innovation is matched by reliability, safety, and global-standard quality. In that sense, the MoU represents not just institutional cooperation, but a strategic investment in India’s defence future.

The information presented in this article is based on publicly available sources, reports, and factual material available at the time of publication. While efforts are made to ensure accuracy, details may change as new information emerges. The content is provided for general informational purposes only, and readers are advised to verify facts independently where necessary.